Solution 2 - Optimizing electric arc furnaces

Up to 100% scrap and green electricity can be used in the EAF

When steel has served its purpose after a few decades, it becomes scrap. However, this scrap remains a high-quality raw material. It can then be recycled as often as required without any loss of quality and fully returned to the economic cycle.

According to the example calculation in ISO 14404.2, 0.396 tons of CO2 are generated during crude steel production. Further savings can be achieved by operating with green electricity.

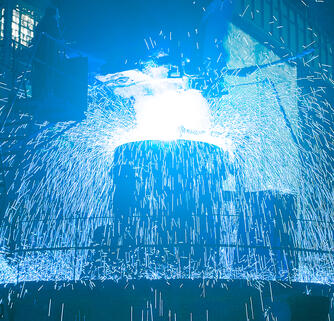

In this process, scrap is melted in an electric arc furnace at high temperatures. Graphite electrodes conduct the electric current and generate the arc, which converts the electrical energy into heat of fusion with very good efficiency and high energy density. No iron ore is used here and virtually no CO2 is produced during the actual process. Nevertheless, most of the electricity needed still comes from coal-fired power stations, so that CO2-emissions occur at an earlier stage. Due to the limited amount of scrap, it is not yet possible to do without iron ore completely.

The electric steel route is often seen as a bridging technology on the way to the production of "green steel". However, this manufacturing process cannot come close to covering the entire range of goods and market requirements. In any case, the achievable CO2-product footprint (PCF) is already very good.

- Lower CO2-emissions: Compared to the blast furnace route, which uses coking coal as a reducing agent, the electric steel route has lower CO2 emissions. Instead of coal, electrical energy is used as the primary energy source, and this electricity can come from renewable energy sources such as wind, solar or hydropower. This significantly reduces CO2-emissions.

- Flexibility in the energy source: The electric steel route makes it possible to choose the energy source flexibly. This means that steel production can be switched to renewable energy sources if required, which is an important step towards low-carbon or carbon-free production.

- Increased efficiency: Electric arc furnaces and electric arc furnace units are more efficient in terms of energy consumption and heat recovery compared to conventional blast furnaces. This results in less energy loss and more sustainable production overall.

- Recycling scrap: The electric steel route often uses scrap as the main raw material, which reduces dependence on iron ore. This helps to conserve natural resources and reduce environmental impact.

- Lower environmental impact: The electric steel route not only reduces CO2-emissions, but also minimizes other environmentally harmful effects, such as the emission of pollutants and waste.

- Limited additionality: In relation to the electric steel route, additionality means that the transformation efforts must go beyond what has already been applied and achieved.